Support Services

Across Africa

your business goals

and excellence

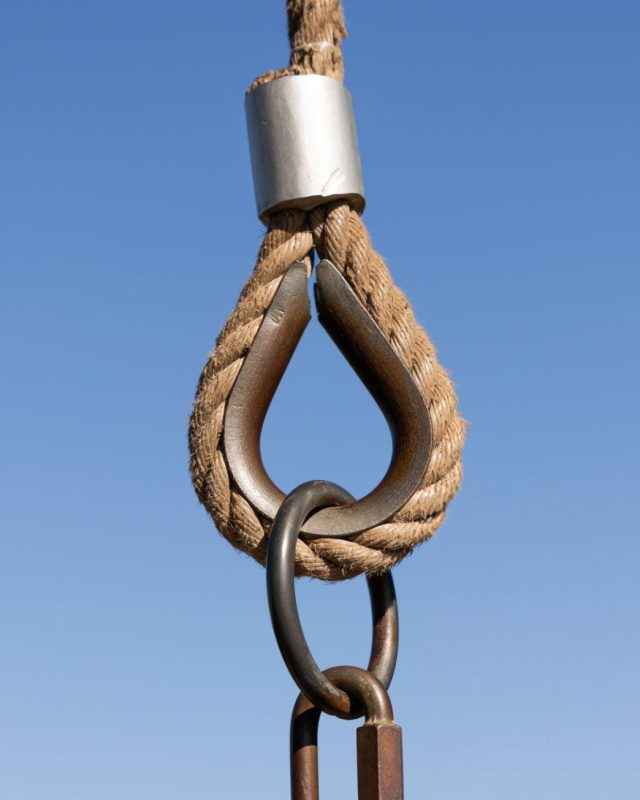

Inspection Services

and Supply of Lifting Accessories

ProductsHigh-Quality Products Tailored

for the Oil & Gas Sector

About UsGlobal Reach, Local Expertise in Oilfield Services

Incorporated in 2008, Omni Energy Ltd is a company that specializes in the delivery of value-added oilfield support services to companies in the upstream petroleum sector. We have expanded our capacity and footprint in the oil and gas industry by building strong relationships with manufacturers and suppliers in Europe and Asia.